Lean 5S

Written By Matthew Brownoff

Description

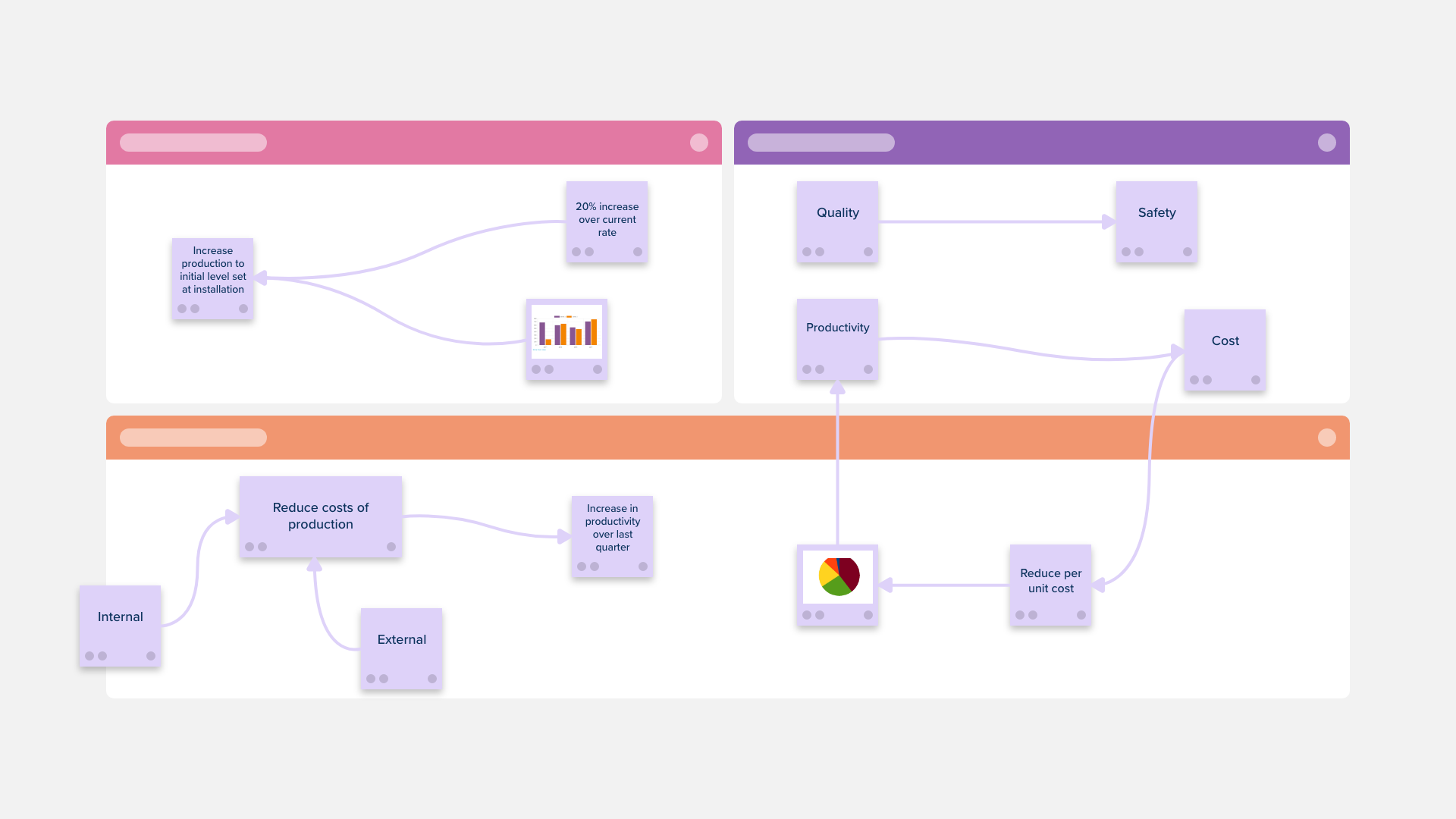

The goal of using the Lean 5S Template is to improve workplace efficiency and increase the value of products or services for customers. The 5S represents five translated Japanese words that describe the steps of a workplace structure — Sort, Straighten, Shine, Standardize, and Sustain.

The template is divided into six sections in order to include Safety, which is now commonly added into this process. In simple terms, this methodology helps remove items no longer needed (sort), organize to optimize efficiency (straighten), clean the area in order to more easily identify problems (shine), implement consistency (standardize), develop organized behaviours (sustain), and ensure that all activities are conducted safely (safety).

Featured