8 Wastes Checklist

About the 8 Wastes Checklist Template

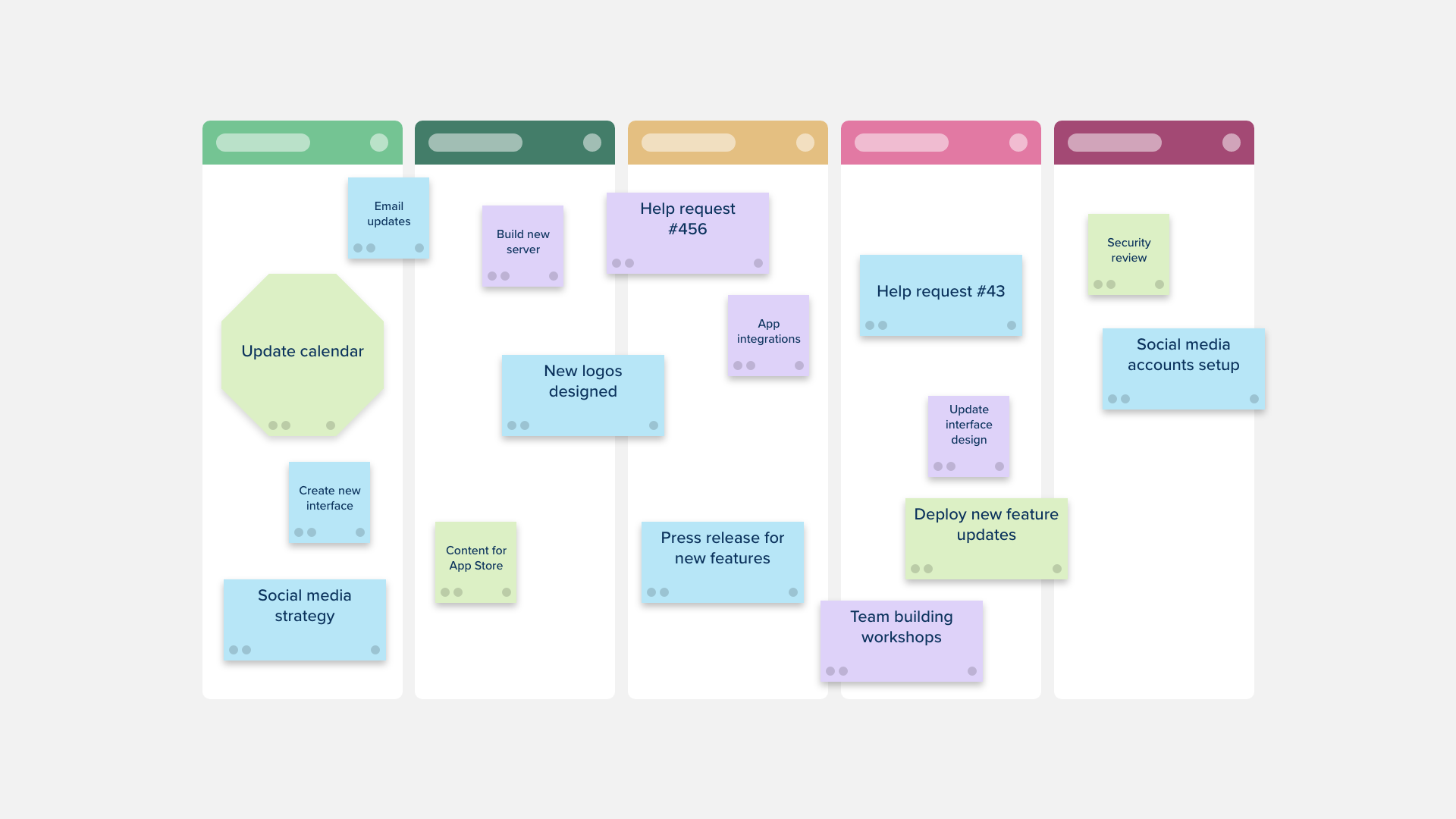

Based on the 7 Wastes of Lean methodology developed by Taiichi Ohno, the Chief Engineer at Toyota, as part of the Toyota Production System (TPS). The 8 Wastes Checklist Template is set up to help you determine which steps or actions in your process are non-value adding. The 8 Wastes of Lean are Defects, Overproduction, Waiting, Non-Utilized Talent, Transportation, Inventory, Motion, and Extra-Processing.

Defects are the products or services that are not to spec and will require resources to fix, Overproduction means there is too much of a product or service, Waiting refers to a stall in the process, and Non-Utilized Talent are employees who are not engaged. Transportation refers to unnecessary items or information being moved around, Inventory is anything valuable that is sitting idle, Motion refers to people or information that has to move around due to a poorly planned workspace, and Extra Processing has you look at activity that is not necessary to your process.

Learn more about how to use this process in our article Your Guide to Adopting Lean Development with the Agile 8 Wastes Checklist

Not working within an Agile framework?

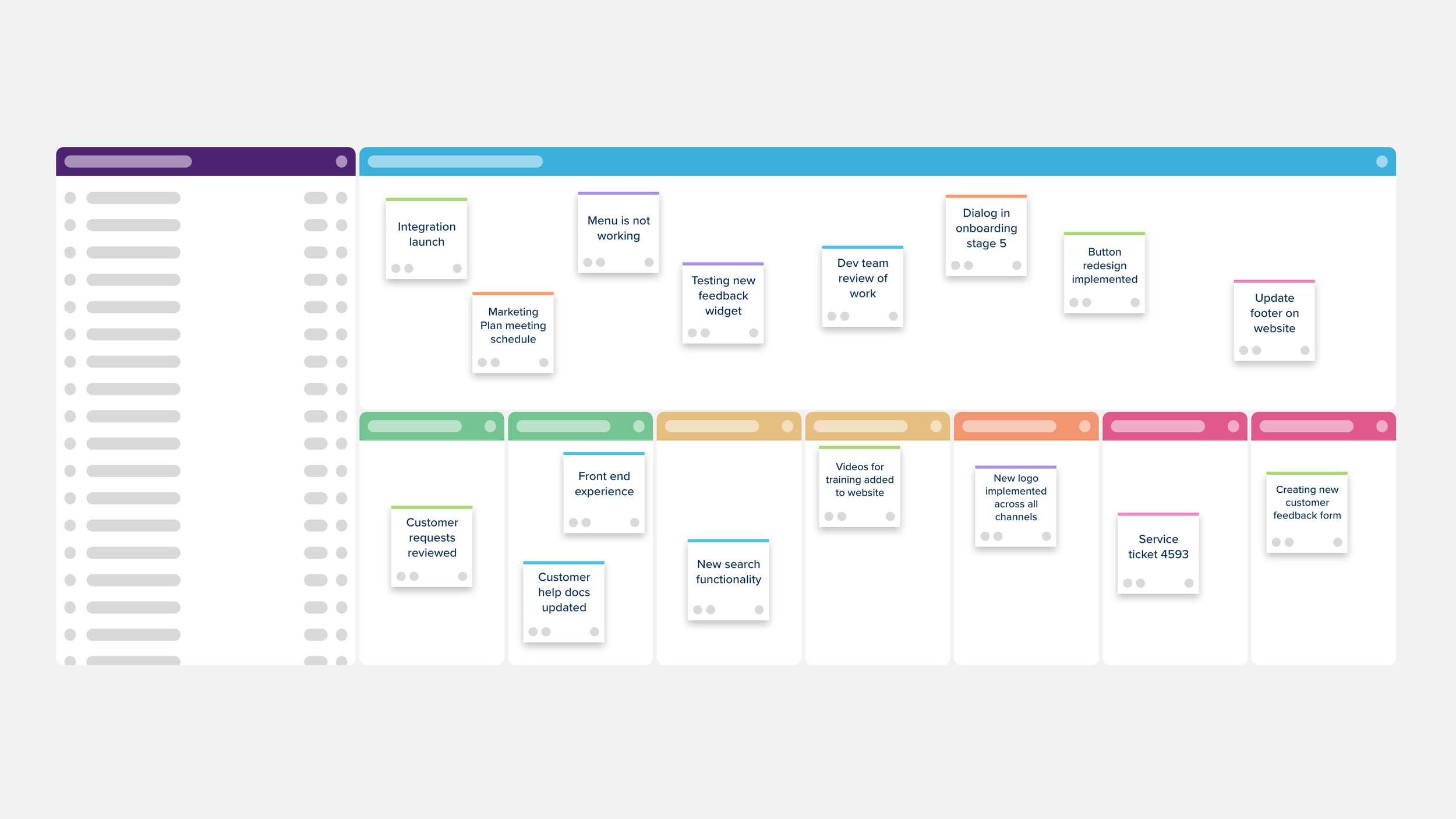

No problem. This 8 Wastes Checklist Template is a powerful tool designed to encourage efficient workflow management within any project. By visualizing task dependencies, you can proactively identify potential roadblocks and optimize your team's execution.

This template is more than a rigid structure; it serves as a springboard to inspire your unique project needs. Whether you're utilizing Agile methodologies, traditional project management frameworks, or any other approach, Stormboard’s 8 Wastes Checklist Template can be effortlessly adapted to your specific workflow.